We source premium-quality, eco-friendly jute fibers from trusted suppliers who follow sustainable farming practices

The raw jute is thoroughly inspected to ensure its strength and texture meet our manufacturing standards

The jute is then stored in a secure, well-ventilated warehouse to maintain its quality until it is ready for processing

The raw jute fibers undergo a series of processes including retting, stripping, and drying, to make them ready for weaving

The fibers are softened through traditional methods to make them easier to work with

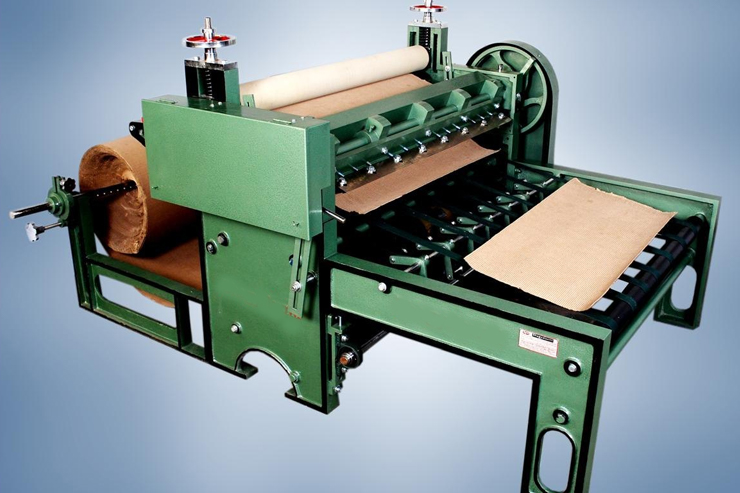

These processed fibers are then spun into yarn using spinning machines

The spun jute yarn is woven into fabric using automatic and semi-automatic looms

Our weaving facility produces different grades and textures of jute fabric depending on the type of bag being manufactured (shopping bags, promotional bags, etc.)

The fabric is inspected for quality at this stage to ensure there are no defects

The woven jute fabric is then dyed in eco-friendly, non-toxic dyes if colored bags are required

For custom designs, logos, or branding, the fabric undergoes printing using screen printing, heat transfer, or water-based ink printing methods

Each design is carefully printed to ensure high-quality, long-lasting graphics that are vibrant and eco-friendly

Once the fabric is ready, it is cut into desired shapes and sizes based on the specifications of the bag design

Precision cutting tools are used to ensure consistency across all products, with minimal waste

Handles, straps, and other accessories are also cut and prepared for assembly

The cut fabric pieces are transferred to the stitching section, where skilled workers stitch the bags using industrial-grade sewing machines

Special attention is given to the strength of the stitching, particularly around the handles and seams, to ensure durability

Any additional features like zippers, buttons, or inner linings are also attached at this stage

Each finished bag undergoes a strict quality control process, where it is inspected for stitching, printing accuracy, and overall craftsmanship

Bags that meet our high standards are passed for packaging, while any defective items are either reworked or recycled

We ensure that every bag is durable, attractive, and eco-friendly before it reaches the customer

Finished bags are packed in eco-friendly materials to prevent damage during transportation

Our packaging process is designed to minimize waste and ensure the bags reach customers in perfect condition

The bags are dispatched to clients and distribution centers through our logistics network, ensuring timely delivery

Waste Management

Leftover jute materials and fabric scraps are recycled and reused in new production cycles

Energy Efficiency

Our manufacturing units are equipped with energy-efficient machinery to reduce our carbon footprint

Eco-Friendly Products

The jute bags we produce are biodegradable, recyclable, and contribute to reducing plastic waste

With a focus on both quality and sustainability, our jute bag manufacturing process ensures that each bag is not only durable and stylish but also environmentally friendly